What is Viscose Fabric?

14/01/2025 / Reading time: 8 mins.

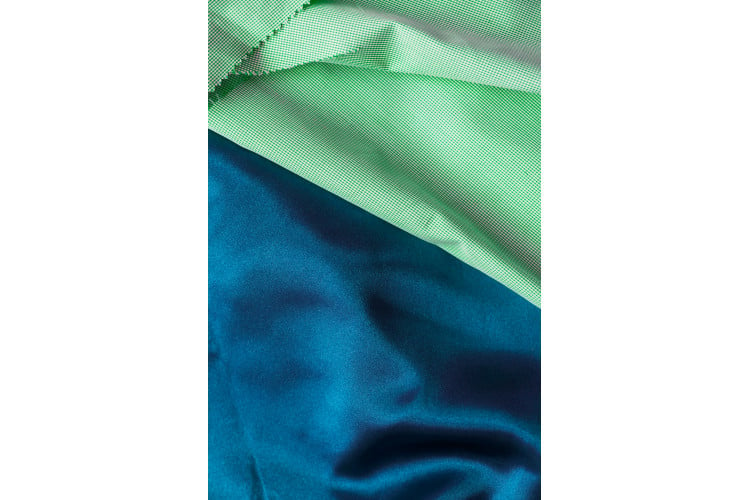

Viscose fabric is a semi-synthetic material that has become popular for its luxurious feel, versatility, and affordability. In the textile industry, it is commonly referred to as rayon and is often seen as an affordable alternative to natural silk. The smooth texture, breathability, and beautiful draping of viscose make it a top choice for wholesale bohemian clothing items. While viscose is praised for its comfort and elegant appearance, it also presents particular challenges, particularly in maintenance and environmental impact.

Viscose comes from the word "viscous," which describes the thick solution used during the fabric's manufacturing process. Viscose is produced from cellulose, a natural polymer in plant fibers, especially wood pulp. Despite being chemically processed, it retains a soft and breathable nature similar to natural fibers like cotton and silk. Viscose can be found in everything from dresses and blouses to linings and upholstery, making it a highly versatile fabric in the fashion and textile industry.

What is Viscose Fabric Made of?

Made chiefly from cellulose extracted from wood pulp, viscose boho maternity dress is often produced using cellulose from fast-growing trees, including eucalyptus, beech, and pine. In some cases, other sources of cellulose, like bamboo, are also used. A detailed look at the key components and processes involved in producing viscose fabric follows:

- Cellulose: The fundamental material is natural cellulose, a polymer that forms the key structural element of plant cells. This cellulose is chemically altered to create a fiber that can be utilized in textile creation.

- Sodium hydroxide: Also known as caustic soda, sodium hydroxide is used to treat the cellulose pulp, turning it into a more workable form known as alkali cellulose.

- Carbon disulfide: When added to alkali cellulose, this chemical forms cellulose xanthate, which is subsequently dissolved in a sodium hydroxide solution to create a thick, viscous liquid.

- Water: Water plays a crucial role throughout the process, from washing the pulp to diluting the viscous solution before it is spun into fibers.

The resulting viscous solution is filtered, aged, and spun through spinnerets to create fine filaments. Once these filaments are solidified, they form the woven or knitted fibers into viscose fabric.

What Are The Pros and Cons of Viscose Fabric?

Viscose fabric, like any textile, has advantages and drawbacks. Knowing these can help consumers make informed choices when buying and maintaining viscose products.

Pros of Viscose Fabric

- Softness and Comfort: With a smooth, silky feel, viscose is incredibly soft. Its lightness adds to its comfort, particularly in warmer conditions.

- Breathability: Since viscose is derived from natural cellulose, it retains the breathable properties of plant-based fibers. Its ability to allow air circulation makes it ideal for warm-weather wear.

- Drape and Elegance: One of viscose's defining characteristics is its elegant drape. It flows smoothly and hangs gracefully, which is why it is commonly used for dresses, skirts, and blouses.

- Versatility: Viscose's versatility allows it to be mixed with fibers like cotton, polyester, and spandex, producing fabrics with unique textures and properties.

- Vibrant Shades: The fabric efficiently absorbs dyes, leading to bright and enduring colors. Consequently, baggy boho pants with eye-catching patterns and prints are favored.

Cons of Viscose Fabric

- Prone to Wrinkling: Viscose fabrics are prone to wrinkling, a significant drawback that can cause garments to lose their crisp appearance after wear or washing.

- Delicate and High Maintenance: Viscose is sensitive to water and can lose shape or strength when wet. It often requires hand washing or dry cleaning to maintain its appearance.

- Environmental Concerns: The chemical processes involved in viscose production can harm the environment if not handled appropriately.

- Susceptible to Shrinkage: Improper washing or drying can cause viscose garments to shrink. Carefully following the care instructions is crucial to prevent fabric damage.

- Durability Issues: While viscose provides a soft and luxurious feel, it lacks the durability of some other fabrics. Over time, repeated wear and washing can cause pilling and fraying.

Recognizing the advantages of viscose fabric, including its smooth texture, airiness, and rich colors, enables consumers to value its qualities and select it appropriately for their preferences. This fabric is soft, breathable, and elegant, making it ideal for fashion, but it requires delicate care and environmental concerns. Awareness of these factors supports consumers in making sound decisions.

How is Viscose Fabric Made and What is it Used For?

The production of viscose fabric involves several chemical and mechanical processes.

Steps in The Production of Viscose Fabric

- Harvesting Wood Pulp: The process begins with harvesting wood from trees such as eucalyptus, beech, or pine. Bamboo is also widely used as a cellulose source for specific types of viscose.

- Treating the Pulp: The wood is cut into small fragments and chemically processed to extract cellulose. The cellulose is then purified and bleached to remove any unwanted substances.

- Alkali Treatment: To create alkali cellulose, the purified cellulose is soaked in a sodium hydroxide (caustic soda) solution. This process breaks down the fibers and streamlines handling during production.

- Xanthation: Carbon disulfide is added to the alkali cellulose, forming cellulose xanthate. This yellow, crumbly substance is crucial for transforming the solid cellulose into a liquid form.

- Dissolving and Aging: The cellulose xanthate is mixed with a diluted sodium hydroxide solution to form a viscous liquid, which is then aged to obtain the desired viscosity and qualities.

- Spinning: The viscous solution passes through small spinnerets into a sulfuric acid bath, where it solidifies into filaments, which are later spun into yarn or thread.

- Washing and Drying: The fibers are thoroughly washed to remove any remaining chemicals, then dried and wound onto spools for further processing.

- Weaving or Knitting: Viscose yarn is woven or knitted into fabric, which can be dyed, treated, and applied in various ways.

The production of viscose fabric converts natural cellulose into versatile fibers, prized for their softness, breathability, and adaptability in textiles.

Uses of Viscose Fabric

- Clothing: Viscose is a popular fabric in the fashion industry. It is used for dresses, blouses, boho skirts, and trousers. Its graceful drape makes it especially favored for evening and formal wear.

- Linings: Viscose, known for its smooth texture, is often used as a lining in jackets, coats, and bags.

- Industrial Applications: The versatility of viscose extends to industrial products, including tire cords and medical gauze.

- Blended Fabrics: Viscose is regularly blended with cotton, polyester, or spandex fibers to improve the fabric's characteristics. These blends are typically used in sportswear, casual wear, and undergarments.

Viscose fabric stands out as a material that bridges natural and synthetic fibers. Its comfort, elegance, and breathability contribute to its popularity in fashion. However, it also has drawbacks, such as wrinkling, delicate care requirements, and environmental concerns associated with its production.

By understanding the pros and cons of "viscose fabric," consumers can make more informed choices about purchasing and maintaining garments made from this versatile material. Whether you're looking for elegant evening wear, comfortable everyday clothing, or plus size clothing, viscose offers a luxurious feel at an affordable price, making it a valuable addition to any wardrobe. Bandito offers quality, one-of-a-kind Bohemian fashion pieces to help you express your free-spirited style